300.000 TPY DRI plant in China

- Zoom

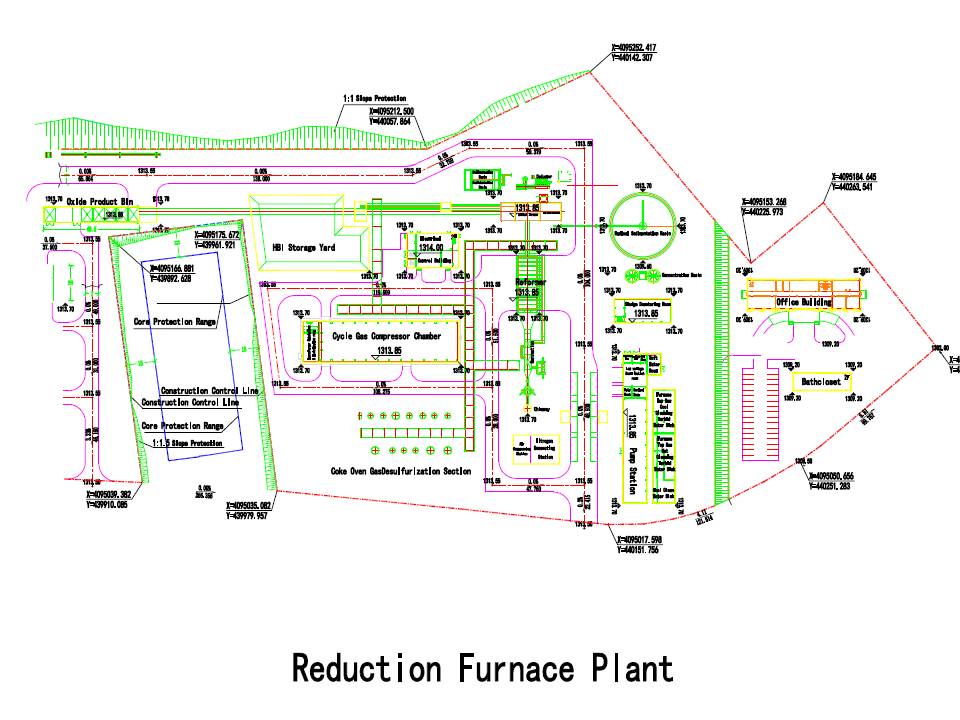

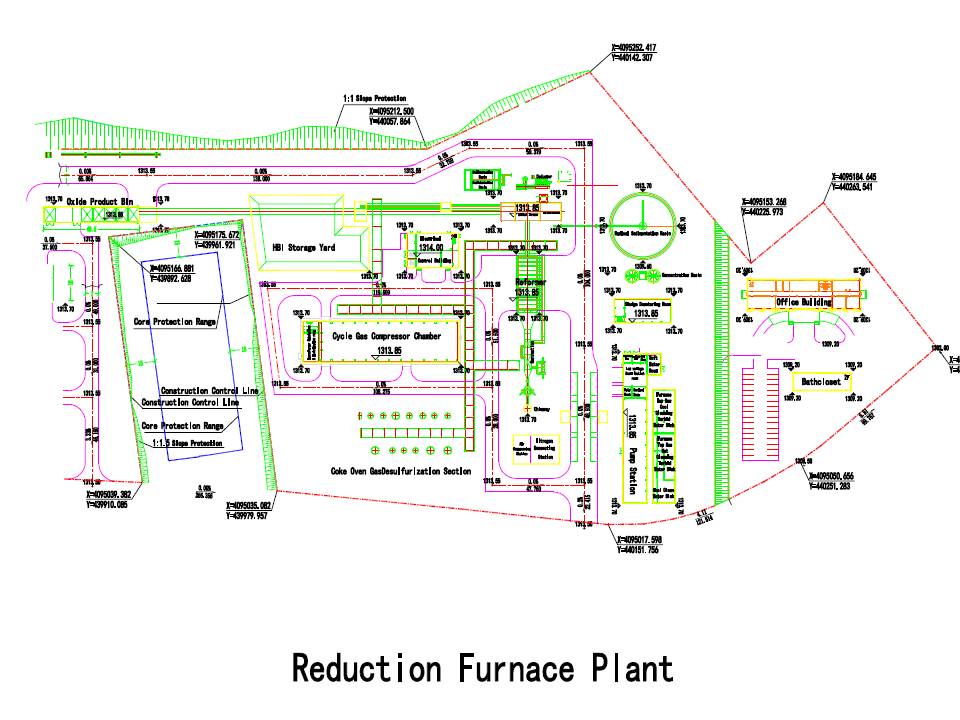

- LAYOUT

China ShanxiTaihang Mining Co.Ltd. and MME GmbH Signed a contract for supply of technology, engineering and equipment for the installation of a new plant for the production of DRI ( Hot Briquetted Iron) using Coke Oven Gas as Reducing Gas.

The Contract signed in May 2013 create a new vision for the future of the Steel Industry in China

The activities of Enginering for the Shaft Furnace by MME GmbH are on completion and the Manufacturining of the equipment is in progress.

The Civil activites at site are started

China's metallurgical industry to become cleaner

Shanxi Taihang Mining Co. Ltd. will become China's first company to use coke oven gas as an alternative to natural gas to get reduced iron in industrial production after striking a contract to import Iranian technology on Monday.

Under its contract with Mines and Metals Engineering (MME) GmbH, owned by the Iranian government and based in Duesseldorf, Germany, Shanxi Taihang Mining will use world-leading processing technology and equipment to lift its iron productivity and reduce emissions.

Technically termed as direct-reduced iron process, the technology can raise the purity of iron to 98 percent, according to Weng Yuqing, chief expert of China's Ministry of Science and Technology.

Traditional blast furnace iron-making, which generates 80 percent of China's total iron and steel output, however, only results in an iron purity of 60 to 70 percent.

"The collaboration will allow Chinese companies to use coke oven gas for the first time to directly reduce iron for industrial purpose, " said Weng, also an academician with the Chinese Academy of Engineering.

He said the technology is suitable for China's metallurgical industry and fits the country's vision to build an energy-efficient society with low carbon dioxide emission.

According to a Shanxi Taihang Mining statement, the direct-reduced iron project with an annual capacity of 300,000 tonnes of iron is situated in the Longquan Industrial Innovation Demonstration Park of Zuoquan County, Jinzhong City of north China's Shanxi Province.

The park with a total planned investment of 15 billion yuan has used 2.3 billion yuan in its first phase of construction, which also includes the renovation and expansion of a colliery with a production capacity of 1.5 million tonnes, a 2.1 million-tonne coal washing project and a 1-million-tonne coking project.

All these projects will be fully operational successively from 2015 to 2016.

The technological solution is MME GmbH's up-to-date innovation and patented in Germany